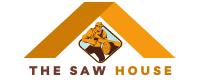

It is hard to know the difference between the Table saw splitter and vs receiving knife. But we are going to know. All about the table saw splitter and the riving knife. With some renowned specifications that we are going to know later.

Table saws made available to buy nowadays need to have a riving blade. Rather than a splitter. The distinction is that a riving blade goes all over with a sharp edge.

With keeping a similar good way from the cutting edge. While a splitter-mounted gatekeeper stays at a fixed tallness.

So, thus, it has kept mounted to the table trunnion to keep an angle with the edge.

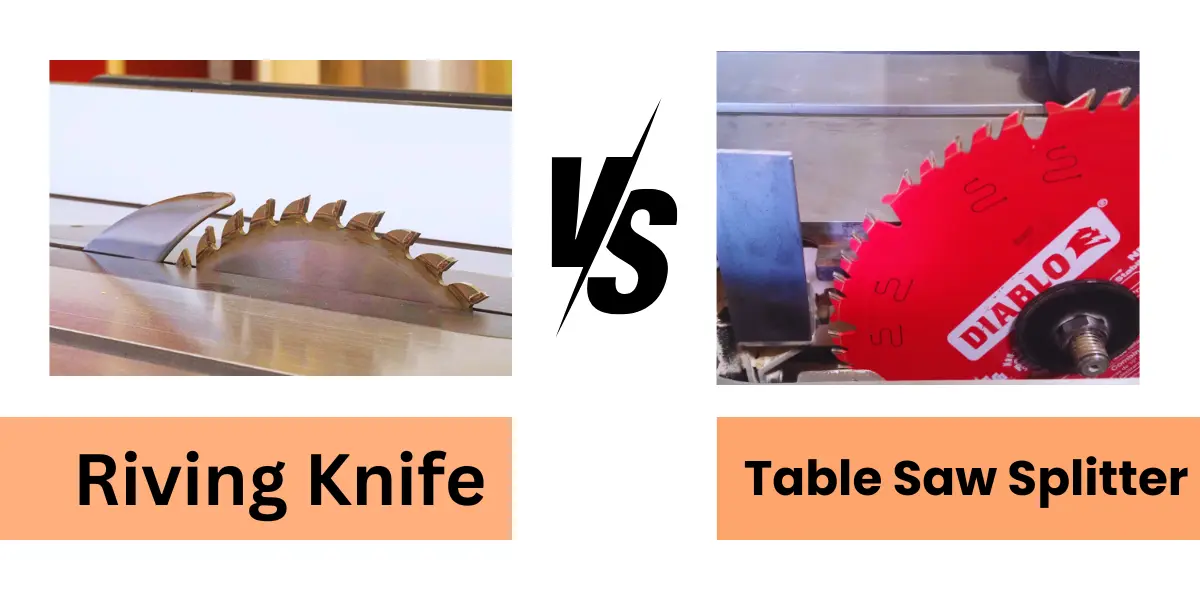

What Is The Table Saw Splitter?

A splitter is a fixed edge of comparable thickness to the pivoting saw. Sharp edge mounted behind it to keep the board from squeezing. Internal into the saw kerf and official on the saw cutting edge. Causing a perilous payoff.

What Is The Riving Knife?

A riving blade is a security gadget introduced on a table saw. Which has observed round? And an outspread arm saw used for carpentry.

Connected to the saw’s arbor. It fixes comparatively with the edge. And moves with it as edge profundity is adjusted.

Table saw splitter Vs riving knife

Both sit behind the sharp edge. To forestall the different sides of a cut bit of wood.

From squeezing or pivoting into the cutting edge. Which keeps the workpiece from kicking back at the administrator.

Be that as it may, a splitter ordinarily doesn’t change stature. While a riving blade raises and brings down the edge.

Additionally, the head of a genuine riving blade stands simply lower than the head of the sharp edge.

so it doesn’t need to be taken out for most non-through cuts. For example, dadoes, and rabbets.

Each table saw accompanies a splitter that holds a sharp-edge watchman. And you can include a reseller’s exchange splitter. For example, the one indicated base, without a gatekeeper.

Before long, riving blades will be similar to normal. Guarantors Labs (UL) made them a UL-posting prerequisite for a new table saw models.

Presented by January 2008. The existing table saw models are in heritage until 2014.

See more about bosch vs Dewalt table saw

What To See Before Buying Splitter

The electric power

Like most electric instruments. Electric log splitters will, in general, be littler. And simpler to store and simpler to move.

Most electric models run somewhere in the range of 5 and 6 tons. So, they can handle large logs up to 10 crawls.

In distance across without an excessive amount of strain. What’s more, since electric models produce no vapor.

They have sheltered to use in the carport. The disservice is that you’re restricted by the length of your extra rope. On how out of sight the yard you can go with your electric splitter.

The tonnage

Splitters have been appraised. With huge amounts of parting pressure, they produce. The more parting weight you have. The bigger the width the harder the kind of wood.

You will have the option to part. Regardless of the gas or electricity. Models delivering 5 or 6 tons.

The gas power

Doing bigger jobs the gas power is a vital element to know. For logs bigger than 10 inches and harder kinds of wood.

Gas-fueled models are the best way to go as they produce higher weights. 20 tons or more expected to take care of business.

Level splitters are incredible for parting pieces you can without much of a stretch lift. Yet for heavier bits of bigger width.

You will need to get a model that parts vertically. Double wedge models have been planned so that on the off chance.

Search for models that are anything but difficult to clean. And have hardcore hoses and connectors that will wear longer.

Furthermore, be certain the machine you pick has parts. With promptly accessible administrations.

What To See Before Buying a Riving Knife

Functionalities

The table saw a use for cross-cutting and tearing purposes. Cross-cutting cuts the board width-wise.

And tearing cuts the board longwise along the grain. Different conditions are experienced while tearing and cross-cutting.

Helpless sharp edge or fence arrangement, administrator blunder, or prior worries.

By cutting the wood. That delivery can cause unique and devastating aspects.

A riving blade rides inside the kerf. Turning on the saw’s arbor corresponds to sharp edge tallness. For making even holes in between the two cut sides of the board.

Forestalling sticking could make the stock be strongly launched.

Mechanics

On most table saws, the riving blade mounts to the saw’s trunnion. The solid instrument underneath the saw table.

That raises and brings down the saw’s sharp edge. Ordinarily, the riving blade has a delivery instrument.

This can be met by eliminating the table supplement. From the head of the saw table.

By and large, this delivery instrument permits. The riving blade to balance higher or lower. All in accordance with the saw edge.

As the blade is a mold with the goal. Cutting teeth and the edge of the blade is under 1/4 inch. When keeping the two parts of a newly cut board isolated.

As it pushes through the cutting edge. The riving blade raises and brings down alongside. The considered edge to be its profundity is balance.

Permitting the riving blade to embrace. The edge regardless of what position it is in. In contrast to a splitter. Which must be canceled from the saw for crosscutting.

A riving blade can stay set up for crosscuts. And any kind of cut where the saw kerf runs altogether. Through the thickness of the board. There are a few occurrences in which the riving blade isn’t fitting.

What is kickback

Saw sharp edge “getting” happens more regularly during tearing than cross-cutting.

Although is riskier with a roundabout saw as zones of the roundabout sharp edge near.

The cutting zone is moving in various ways. On the off chance that a bandsaw snatches. Where the wood squeezed down to the machine table.

On the off chance that a table saw snatches at the back of the cutting edge. Where the teeth are ascending from the table.

It lifted the wood in an upward direction. The wood is then prone to get the teeth on the head of the cutting edge.

And tossed advances fast toward the administrator. This mishap is termed “kickback”.

Kickbacks formed

Table saw payoff may happen if the saw’s fence doesn’t correspond with the edge. But it is somewhat nearer to the back.

In contrast with the front. Which helps the fence to move the wood to the back of the blade.

Furthermore, when cross-cutting sheet materials that are broader. In contrast with the cut length.

Which turns and jams against the sharp edge. On the off chance that a legitimate cross-cutting dance isn’t used.

The fence ought to balance or slide forward. Or a bogus fence included. so the finish of the fence stops close to the sharp edge.

Leaving a free space for the slice off to turn into without binding. The payoff may likewise happen when a free bit of wood. Newly cut free slips against the rear of the sharp edge.

Aside from the measures over. This “falling board” may need an associate to control it.

Controlling Kickbacks

Anti-kickback agents include a kickback pawl and a feature board. The kickback pawl fits with honed ratchet teeth. On a free-swinging pawl connected to the watchman.

Which limits aboard during a payoff. This blend may need abnormal change. And is inadequately contrasted with the splitter?

Feather board is a well-being gadget. Which apply weight sideways. Withholding the workpiece against the saw fence.

It can diminish the danger of a payoff growing. Yet won’t limit the board if one happens.

Preference Of Riving Knife Over the Splitter

It shouldn’t have been taken out of the saw. When cross-cutting or doing a visually impaired non-through cut.

As it doesn’t reach out over the head of the saw edge. On the off chance that it isn’t eliminated. The administrator can’t neglect to return it.

It sits nearer to the back edge. Making it considerably more compelling and less space for the stock. To move into the way of the edge

It gives some extra insurance to the administrator. Hindering contact to the back of the cutting edge.

Especially in those conditions where the stock is pulled. It is free and won’t meddle with other cutting-edge watches and residue gatherers.

It accomplishes the entirety of this by connecting to the saw’s arbor. Permitting it to move with the considered sharp edge.

To be the edge is raised, brought down, and tilted. Riving blades fit to hand-hold electrical round and fueled miter. Although cross-cut saws are referred to conventionally as cleave saws.

Preference Of Table Saw Splitter Over the Riving knife

A splitter is fixed. So, it must be set far enough back on the throat plate of the table saw. To forestall obstruction. When the sharp edge rises to its full tallness.

At the point when the cutting edge has raised to make profound cuts.

The separation between the splitter and the edge is somewhat small. So, the splitter viably forestalls the payoff.

As the sharp edge brought down, in any case. The separation between it and the splitter develops. Leaving space for wood to contact the teeth.

Additionally, when the cutting edge is inclined to make a calculated cut. The splitter must be taken out.

Splitters are typically particular to reinstall. So, it gets enticing to leave them off for good.

Splitters have a decisive advantage over riving blades in a single respect. Although, they can retrofit your current table saw.

Though a riving blade can’t be. Some assurance is superior to no insurance.

Superior to nothing. Splitters are an astute expansion to any observed. That doesn’t have a manufacturing plant that introduced the riving blade.

Main Differences Between The Riving Knife and Splitter

All table saws produced available to buy these days need to have a riving blade rather than a splitter. The contrast between the two is that a riving blade goes all over with the edge.

Keeping similar good ways from the edge. While a splitter-mounted gatekeeper stays at a fixed tallness.

Thus, it is kept mounted to the table trunnion. For making an angle with a sharp edge. Likewise, the new necessities state.

The receiving blade must have the option to cancel effectively. And when introduced it will be following the sharp edge with no change required.

Why? Examination shows that when a splitter is used it is often taken out. Say to make a dado cut. Sometimes, if at any point, was the splitter reinstalled.

The examination further uncovers. Most tables saw wounds are the consequence of payoffs.

The significance of using viable well-being strategies can’t be overemphasized. Payoffs are for the most part brought.

About a fence that isn’t adjusted appropriately. Consuming on one side of the sharp edge is an admonition your fence may need alteration.

At times payoffs can happen while tearing a load up. At times the material needs to spring back together.

Because of worries about the grain of the wood. Making its squeeze on the rear of the cutting edge. Both riving blades and splitters intend to keep the wood constrained.

Open to lessen this from occurring; at the same time. A riving blade is consistently a fixed good way from the edge.

Normally 1/4-3/8″ though a table saw splitter can be a decent 2″ from the sharp edge. As a result of how it keeps mounting.

The more slender the stock the bigger this hole becomes. And even more of a payoff threat. Acknowledging most carpenters will drop the edge.

Watch most new plans permit you to either cancel or raise the watchman. While leaving the riving blade set up.

See more about Table saw vs chop saw

Table Saw Splitter And Riving knife Aftermarket

The vast discussion on the table saw splitter vs riving knife.

This leads the conversation to the table saw and receiving knife aftermarket. Which comes up when the manufacturers come up with a shortage.

Table Saw Splitter Aftermarket

They seem like an amazing option in contrast to the stock-style splitter.

And only great audits on carpentry discussions from different carpenters. In this composition, they appear to have models.

To cover the three kerf sizes. The standard unit is all plastic. Although the master pack has a plastic secured steel center.

The two packs go with a dance for mounting the splitters. And a boring tool for boring the gaps. The steel-cored unit sounds somewhat strong.

They’ll work with zero-leeway embeds. However, you’ll need to make your own or buy spaces made for your specific table saw.

On the off chance that you would prefer not to make your table saw splitter. This appears to be a modest and viable other option.

Riving knife Aftermarket

Splitters are promptly accessible. That is a lot better than the first hardware splitter edge watch.

Biesemeyer presently possessed by similar people that own Delta makes a decent one.

It is anything but a genuine riving blade. It inclines with the edge although doesn’t rise and fall with it.

Joins and eliminates without any instruments. After a unique establishment.

Top Preferences – Table Saw Splitter vs Riving knife

The contrast of the table saw splitter vs riving knife. The vast discussion will blow up your mind. With the acknowledgment of the newest and known splitter and riving knife.

Top Known Suggestions For Table Saw Splitters

Delta table saw splitter

Included with Delta Select Cutting Edge Gatekeeper. Payoff insurance for less cash. The Removable Splitter is kept isolated from its holder.

By slackening a handle, making it somewhat less helpful than different units. It is incorporated with the Delta Choice Cutting edge Monitor. Or can be bought independently.

The more up-to-date Delta table saw Splitter fits all Delta bureaus. And contractual worker table saws. Delta planned this removable splitter to go with its Special Sharp Edge Watchman.

Although the splitter is accessible independently. This splitter cancels from its holder by extricating the enormous.

Round handle that braces it set up. While not as helpful to drop as the other two.

This splitter despite everything is anything. But difficult to use. Like the Delta Vanishing Splitter.

The Removable Splitter can be used with meager kerf-cutting edges. It is marginally more extensive.

Then the Vanishing Splitter and not as inclined to twist. The people’s good reviews proved its quality, durability, and use.

MJ table saw splitter

To improve Table Saw Security. The reasonable Miniature Dance MJ Splitter framework is easy to use. Careful, and incredibly compelling. Delivers essential and consume-free cuts.

Low profile splitter likewise fills in as a little feather board. For the guardian piece behind the saw edge.

Intended to use on a Zero Leeway Supplement. With or without the Miniature Dance GRR-Ripper Framework.

Use for making 90-degree cuts. And won’t oblige cuts with an inclined arbor. Incorporates two splitters to do four counterbalances to the sharp edge

The selection of the MJ table saw. This is due to a simple splitter solution for thin kerf blades.

And safety from kickbacks. Also for better cuts and more control on thin pieces of the table saw.

Top Known Suggestions For Riving Knife

Past due guidelines that need all recently planned table saws. Incorporating a riving blade is a major aspect of the cutting-edge watch framework.

Which is making table saws more secure? This slim, hardened, plate of steel is introduced from over the tabletop.

Simply behind the saw blade. Much like a splitter. It intends to forestall the payoff.

Yet, it offers huge points of interest in security and accommodation. Let’s begin the discovery of highly known and used.

JET 708683 Riving Knife

The Jet Riving Knife is an XACTA Deluxe Thin Kerf in Woodworking. Manufactured by the known company name Jet.

The riving blade diminishes the payoff on the table saw. This meager kerf riving blade allows you to use even the most slender edges.

For lessening the kerf squandered increment security. And upgrade execution with this Stream Riving Blade.

Shark Guard

Nowadays a shrewd designer by the name of Lee Styron. Concludes to solve the sawdust problem. And afterward, the Shark Gatekeeper conceived.

Other than being extremely gifted Lee has a bit of humor in his bones. Which mounted sharks face on this pristine Shark Gatekeeper plan.

The gatekeeper has a vacuum connection on its top. In the photograph underneath, you can see the Watchman mount. On the head of the new plan riving blade.

Conclusion

Splitters keep the saw kerf from squeezing on the edge. Causing security issues like a payoff.

Or keeping a piece between the sharp edge and the fence. Past the saw cut from riding up the cutting edge and throwing the piece back at you.

A few payoffs can bring your hand directly into a sharp edge. Riving blades are shockingly better. But inaccessible in some more seasoned models.

They are truly significant for security reasons. They fill two needs. It keeps the cut piece pushed.

Furthermore, keeps the cutoff piece from pressing shut. Authoritatively on the sharp edge.

Resources: https://www.cpsc.gov/Regulations-Laws–Standards/Voluntary-Standards/Topics/Table-Saws